Automated sample clean-up and purification systems for Dioxins (PCDD/F) and PCBs

Meeting the Evolving Needs of Modern Laboratories

Today’s laboratories analyzing diverse matrices for dioxins and PCBs face growing demands. Beyond the pressure to cut costs and shorten turnaround times, there is heightened emphasis on improving efficiency, enhancing personnel safety, and reducing organic solvent use to minimize environmental impact. Regulatory bodies across Europe and North America are increasingly prioritizing these areas. DSP Systems delivers advanced solutions to meet these challenges, empowering laboratories to stay at the forefront of their field.

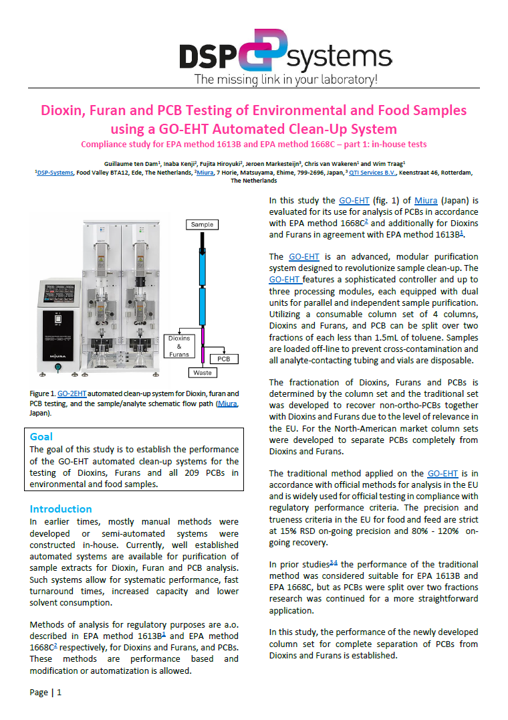

As the official European and North American distributor for the Miura Institute of Environmental Science — a leading Japanese innovator in sustainable “green technology for the future” — DSP Systems offers cutting-edge laboratory solutions. Miura develops and refines technologies that balance efficiency with environmental stewardship. This commitment is embodied in the GO-EHT systems, providing automated, reliable, and eco-conscious sample preparation for dioxins, PCBs, and other persistent organic pollutants.

Key Advantages of GO-EHT Systems

- Minimal organic solvent consumption — hexane: 90 ml per sample; toluene: 5 ml per sample; no DCM required.

- No system–sample contact — eliminates risk of cross-contamination.

- Efficient fraction collection — purified dioxin and PCB fractions collected directly in GC vials.

- Low purified fraction volumes — both dioxin and PCB fractions < 1.5 ml.

- High throughput — up to 6 samples processed simultaneously in under 90 minutes.

- No sample valves — eliminates clogging and maintenance issues.

- No washing programs required — saves time and reduces solvent use.

These advantages make GO-EHT systems a benchmark for fast, safe, sustainable, and contamination-free sample preparation, helping laboratories achieve higher efficiency while lowering costs and environmental impact.